There’s no doubt our industry is still feeling the aftermath of the pandemic, but things are slowly improving, and many K&B businesses have innovated to thrive and serve their customers during this tumultuous time. KBB gathered information from several of them as to the solutions they have put into place and advise for other industry peers.

BSH (Bosch, Thermador, Gaggenau)

According to company CEO Christofer von Nagel, his company is choosing the completely transparent route and immediately providing updates and answers to all customers. He says it is important to openly state that BSH understands their issues and is working on those through a variety of measures, including hiring more factory workers and increasing shifts. In terms of tips for trade professionals to help their clients plan ahead, von Nagel suggests asking them to make decisions quickly so they can put in orders early and be more flexible in their product choices.

Custom Wood Products

Director of sales, Tom Price wrote his own piece on where his Kansas-based K&B business is headed.

Historically, cabinet manufacturers have been able to establish consistent lead times with little fluctuation year after year. The remodeling industry has built processes around these consistent lead times. Fast forward to Summer of 2021, and orders that took five weeks now take 15, with some vendor lead times approaching 30 weeks, and those numbers are climbing.

This is an unprecedented moment in time and who can say when things will ultimately be normalized. Manufacturers are unable to respond to the increased volatility, as most base their material and labor needs off prior-year sales plus a growth percentage; they have no visibility on future order volume from their dealers.

One of the keys to our success in managing workflow has been through an understanding our customer’s sales process. Early in the initial planning stage of a project, dealers will complete a needs assessment, then formulate a recommendation on the cabinetry line that best fits the criteria for the project. When the designer prepares an estimate in our system, they are requested to enter an “Anticipated Delivery Date.” It is a best guess on when they think the project will be cabinet ready. This simple entry provides CWP visibility of future work many months in advance of the actual order placement and is used to place orders for plywood, hardwood, hardware and other materials. We can work with suppliers to have the right mix on hand to meet production demands.

When is the best time to place the order? Most manufacturers will not hold orders; once the order is placed, a ship date is established that cannot be changed. Most job sites do not have the capability to store cabinets for long lengths of time, so designers have been conditioned to place orders under these strict conditions – waiting for that optimal moment to place the order.

At CWP, dealers are encouraged to place their orders sooner than later to reserve a spot on our production schedule. The Anticipated Delivery Date is linked to CWP’s production schedule and is color coded to provide a visual alert to the designer, guiding them on when to place the order. If the date is showing as Green (we have production capacity for that week), Yellow (orders are booking fast), Red: (production is full). It is like making a reservation on Open Table; Book in advance and you are guaranteeing a seat; wait until the last second and you may be shut out. Once the order is placed, your date is guaranteed, and the order will ship on time and complete when you need it. If the project gets delayed, our dealers can contact us and we move production until they are ready to take delivery.

My advice, hurry up and wait. Work with your clients to get all the decisions finalized and get those orders placed now. Be prepared for project delays, and work with vendors on scheduling changes. Focus on the project, set clear expectations, and do not make promises you cannot keep.

Holiday Kitchens/Mastercraft Industries Inc.

This Wisconsin-based K&B business continues to provide its customers weekly updates on lead times, supplier issues, job completions and NCRs. Communication from the company is included below.

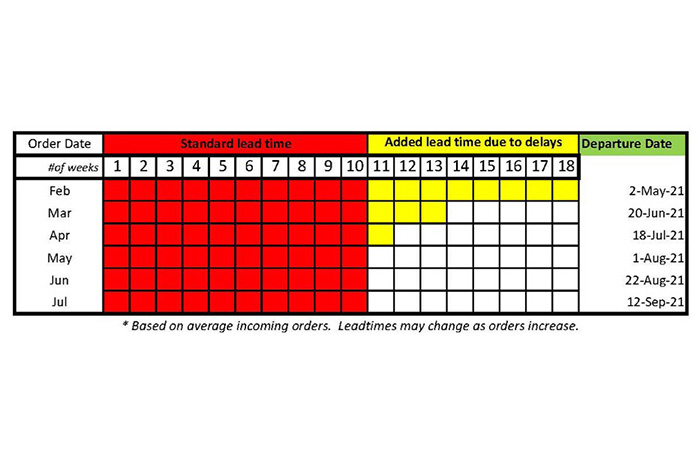

Lead Times

As you can see in the graph below, we are making headway with our lead times. We are still trending toward on-time shipping by late July. Be sure to communicate as accurately to your customers as possible; we don’t want to over promise and under deliver.

Supplier-Related Issues

We continue to experience some supplier-related issues, which are currently quite common in every industry and supply chain. We are confident that by continuing to leverage our vendor relationships, we will be able to keep this to a minimum.

Job Completion and NCRs

We have implemented a strategy to complete these orders that are currently past due. Starting with the oldest orders, our team will focus weekly on a number of orders first and ship them via the selected ship method. Also, once we are back to on-time shipping we will be able to revert to our standard lead time on job completion orders.

Customer Service

We continue to hire more customer service representatives to help handle the influx of calls and emails. Holiday Kitchens is designed to work with reps, the reps field calls from the dealers, and the homeowner works directly with the dealer. We need to maintain this process so that we can stay focused on your projects.

Häfele

For certain products and product groups, this brand is choosing premium or expedited shipping to ensure on-time delivery to its warehouses, as well as bringing new product sources on board to close supply gaps. Hafele has also improved communications with internal team members and customers regarding such things as current stock levels and inbound shipments.

“Two important things to keep in mind. First, we source globally, but serve locally,” said a Häfele rep. “That allows us to leverage partners from around the globe to bring in any product that may be available. Secondly, our catalog offers a variety of product options that allow for the same function but may have a different design or aesthetic. This has allowed us our customers to switch product solutions but often still achieve a similar result.”

Hafele also says those clients who are flexible in their product, material and finish choices are experiencing better timelines on their projects.

Cipriani Remodeling Solutions

Communication from South New Jersey-based Cipriani Remodeling Solutions announced new processes the firm has put into place to overcome these challenges, including a method to get ahead of ordering key materials so projects can stay on track, as well as only a 2% down payment from homeowners and a pay-as-you-go structure throughout a remodeling project. The company has 31 design professionals, including nine PMs to minimize delays from labor shortages.

According to Cipriani, the demand to remodel a home has never been higher during a summer season due to a workforce that continues to shift to a home office environment, the need for more functional space for the family and historically low interest rates.

“We’ve listened to our customers and understand that peace of mind is a top priority when embarking on a remodeling project,” said Jay Cipriani, president of Cipriani Remodeling Solutions. “As we come out of the pandemic, there is so much uncertainty in our industry with supply chain concerns, fluctuating lumber prices and delays. Not only do we have a system in place to provide solutions for those industry-wide question marks, but we also want our customers to feel at ease with the payment structure – whoever has control of the money has the power.”

-Photo credit: EtiAmmos/AdobeStock